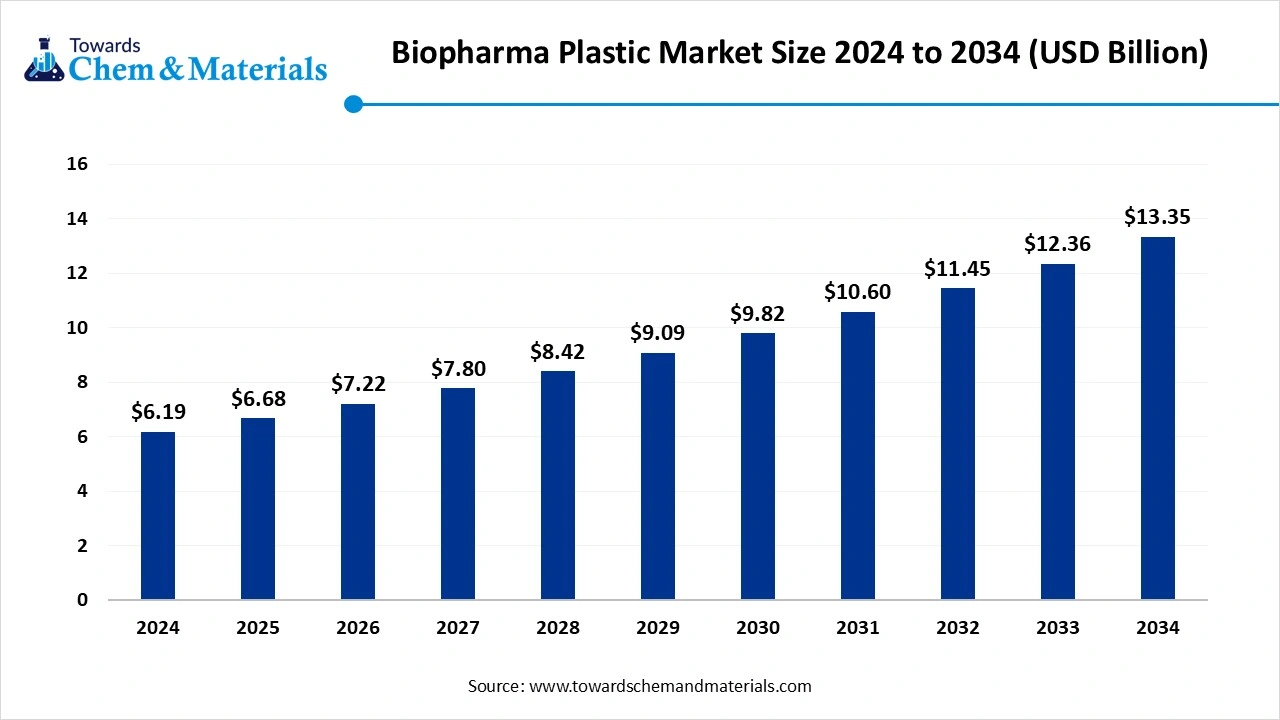

Biopharma Plastic Market Size to Cross USD 13.35 Billion by 2034

According to Towards Chemical and Materials, the global biopharma plastic market size is calculated at USD 6.68 billion in 2025 and is expected to be worth around USD 13.35 billion by 2034, growing at a compound annual growth rate (CAGR) of 7.99% over the forecast period 2025 to 2034.

Ottawa, Oct. 09, 2025 (GLOBE NEWSWIRE) -- The global biopharma plastic market size was valued at USD 6.19 billion in 2024 and is anticipated to reach around USD 13.35 billion by 2034, growing at a compound annual growth rate (CAGR) of 7.99% over the forecast period from 2025 to 2034. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

The Rising demand for single use plastic systems in biopharmaceutical manufacturing is driving the growth of the market.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5674

Biopharma Plastic Overview

Biopharma plastic refers to specialized plastics used in pharmaceuticals and biotechnology, especially for sorting, producing, processing, and delivering biologics, vaccines, and other drug therapies. These plastics are chosen for their high purity, sterilizability, low chemical reactivity, biocompatibility, durability, and ability to maintain regulatory standards. The market driven by expanding demand across medical packaging, drug delivery devices, and single use technologies aimed at reducing contamination risks. Advancements in cell and gene therapy and biologic medicine, plus increasing prevalence of chronic diseases, are also boosting uptake. On the supply side, sustainability concerns and the need for advanced materials (including ones that offer better barrier properties, transparency, and lower extractable) are creating innovation pressure. Meanwhile, stringent regulatory requirements and high production costs challenges.

Biopharma Plastic Market Report Highlights

- The North America biopharma plastic market size accounted for USD 2.54 billion in 2025 and is forecasted to hit around USD 5.14 billion by 2034, representing a CAGR of 8.14% from 2025 to 2034.

- North America biopharma plastic market dominated the global market and accounted for largest revenue share of 38% in 2024.

- By product type, the polypropylene segment held a 24% share in the biopharma plastic market in 2024 due to the growing use of medical devices.

- By application, the bioprocessing equipment segment held a 35% share in the biopharma plastic market in 2024 due to the increasing demand for cell & gene therapy.

- By Usage Mode, the single-use systems (SUS) segment held a 62% share in the biopharma plastic market in 2024 due to the increasing demand for biologics.

- By end user, the biopharmaceutical manufacturers segment held a 48% share in the biopharma plastic market in 2024 due to the growing manufacturing of biopharmaceutical products.

- By distribution channel, the direct sales segment held a 55% share in the biopharma plastic market in 2024 due to the growing focus on customization.

Buy Now this Premium Research Report at a Special Price Against the List Price With [Express Delivery] @ https://www.towardschemandmaterials.com/checkout/5674

Biopharma Plastic Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 7.22 Billion |

| Revenue forecast in 2034 | USD 13.35 Billion |

| Growth rate | CAGR of 7.99% from 2025 to 2034 |

| Historical data | 2021 - 2024 |

| Base Year | 2024 |

| Forecast period | 2025 - 2034 |

| Quantitative units | Revenue in USD Million, Volume in Kilotons, and CAGR from 2025 to 2034 |

| Report coverage | Revenue forecast, competitive landscape, growth factors and trends |

| Segments covered | By Product Type, By Application, By Usage Mode, By End User, By Distribution Channel, By Region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Country Scope | U.S., Canada, Mexico, Germany, UK, France, Italy, China, India, Japan, Brazil, Argentina, GCC Countries, South Africa |

| Key companies profiled | BASF SE; LyondellBasell Industries Holdings B.V.; SABIC; LG Chem; Toray Industries, Inc.; Solvay; Dow, Inc.; DuPont de Nemours, Inc.; Saint-Gobain Performance Plastics; Tekni-Plex; Chevron Phillips Chemical Co., LLC; Exxon Mobil Corporation; Formosa Plastics Corporation; Covestro AG; TEIJIN LIMITED; Mitsui & Co. Plastics Ltd.; INEOS Group; CHIMEI |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Here Are Some Of The Top Products In The Biopharma Plastic Market

- Syringes (including prefilled syringes)- Used for injectable drug delivery; prefilled versions reduce contamination & dosing errors.

- Single-use bioreactor bags- Enables sterile growth of biologics, reduces cleaning requirements; easier scale-up.

- Tubing / fluid transfer lines- Required in bioprocessing, fluid transport, vaccine manufacture; must be sterile, flexible, low leachables.

- Containers, Carboys & Bottles- For storage, transport, and packaging of drugs, biologics, reagents; barrier, clarity, stability are crucial.

- Depth Filters / Filtration Components- Used to purify liquids, sterilize, remove particulates in bioprocess lines. Chemical inertness and pore control matter.

- Disposable Medical Connectors / Fittings- Enables sterile connections/disconnections in single-use systems; reduces contamination risk.

- Vials & Ampoules- For injectable drugs, biologics—plastic helps reduce breakage, weight; high barrier and sterilizability are needed.

- Films & Bags (single-use film systems)- Used for packaging, sterile barrier, sterile film systems in bioreactor bags, media storage.

- Protective Wear (gloves, gowns, masks, etc.)- For operator and environment protection; sterility and barrier properties important.

- Ultra-low temperature tubing / cold chain compatible components- Important in biologics that require cold storage; maintaining material integrity at very low temps (e.g. -80°C).

What Are The Major Trends In The Biopharma Plastic Market?

- Growing adoption of single use systems across biopharmaceutical applications to reduce contamination risk and improve process efficiency.

- Rising interest in advanced polymers like COC/COP that offer high purity, lower extractable and better performance in drug delivery systems.

- Expansion of biologics, cell and gene therapies and personalized medicine fuelling demand for specialized plastics for storage, processing, and packaging.

- Increasing focus on sustainability and reusable or multi use systems due to environmental concerns and regulatory pressures.

- Growth of contract manufacturing organizations (CMOs) as end users, driven by rising research and development and outsourcing trends in biopharma.

How Does AI Influence The Growth Of The Biopharma Plastic Market In 2025?

In 2025, artificial intelligence is shaping the biopharma market by accelerating every stage of the drug development pipeline from early discovery to clinical trials and manufacturing thereby reducing time to market, improving predictive accuracy, and lowering failure rates. AI powered tools are enabling better target identification, toxicity prediction, and optimisation of molecular leads, which helps firm focus resources more efficiently. In clinical trials, AI is improving patient recruitment, modelling trial outcomes, and enhancing data analytics to monitor safety signals earlier. AI is also being used to improve manufacturing through predictive maintenance, real time process monitoring, and supply chain optimisation, ensuring quality and cost control. Altogether, these innovations are boosting productivity, improving the odds of success for new therapeutics, and helping companies respond faster to unmet medical needs.

Biopharma Plastic Market Dynamics

Growth Factors

Could Plant Based Plastics Reshape Single Use Systems?

A move toward plant-derived, biodegradable plastics is gaining traction in biopharma, where companies are exploring materials like polymathic acid (PLA) to replace traditional petroleum based plastics in single use components. This shift aims to reduce environmental burden while still meeting high standards for sterility and regulatory compliance.

Is Environmental Accountability Driving Innovation In Bioprocessing?

Environmental concerns around plastic waste, regulatory scrutiny, and ESG expectations are pushing the industry to rethink how single use systems are designed, used, and disposed of. Lifecycle analysis, waste reduction strategies, and the search for more sustainable manufacturing practices are becoming central to competitive positioning.

Market Opportunity

Could Continuous Bio manufacturing Make Plastics Work Smarter?

There’s a growing shift towards continuous bioprocessing methods which use single use technologies to simplify manufacturing setups, reduce downtime, and improve scalability: using plastics in these systems offers an opportunity to optimize flexibility and reduce costs in production.

Might Data- Driven Waste Tracking Inlock Plastic Circularity?

By improving how companies measure, share, and analyse data on single use system waste specially plastics used in biopharma manufacturing firms can identify hotspots, optimize material use, boost recycling/reuse, and reduce environmental footprint while meeting regulatory and ESG expectations.

Limitations In The Biopharma Plastic Market

- High production cost arising from the need for premium raw materials, specialized manufacturing environments, stringent sterilization, purity and validation processes limits entry and scalability.

- Regulatory burden including rigorous standards, validation, testing, and documentation creates delays and increases expenses for product development and market adoption.

Biopharma Plastic Market Segmentation Insights

Product Type Insights

Why Did The Polypropylene (PP) Segment Dominated The Biopharma Plastic Market?

The polypropylene (PP) segment captured a largest share in the market in 2024. Propylene’s dominance is driven by its excellent chemical resistance, high durability, and ability to meet stringent sterilization standards, making it highly suitable for single use systems, vials and constrainers used in biopharmaceutical processes. Its widespread availability, cost effectiveness, and regulatory compliance also make it the preferred choice for manufacturers looking to ensure quality and safety in bioprocessing applications. The PP segment continuous to remain vital supporting the growing production of biologics and vaccines globally.

The COC/COP segment will gain a significant share of the market over the studied period of 2025 to 2034. These advanced polymers offer superior optical clarity, low extractable, and high chemical resistance, which makes them ideal for lab on chip devices, diagnostic packaging, and drug delivery systems. Increasing adoption of precision medicine, microfluidic devices, and single use technologies is fuelling demand for COC/COP plastics. Manufacturers are investing in research to enhance performance and reduce cost, creating a promising growth trajectory for these high performance materials.

Application Insights

Why Did The Bioprocessing Equipment Segment Dominated The Biopharma Plastic Market?

The bioprocessing equipment segment captured a largest share of the market in 2024. The dominance stems from the increasing reliance on single use technologies in bio manufacturing, where bioprocessing equipment such as mixers, storage bags, and tubing made from high quality plastics reduce contamination risks and enhance operational efficiency. Continuous advancements in biologics and vaccine production have amplified the demand for plastic based bioprocessing solution that ensure sterility, reproducibility, and cost effective production.

The drug delivery segment is expected to grow with the highest CAGR in the market during the studied years. This growth is driven by the rising prevalence of chronic diseases and increased demand for safe, convenient, and precise delivery systems. High purity plastics enable the creation of prefilled syringes, infusion sets, and micro dosing devices, all critical for biologics and vaccines. Innovative materials and designs that improve patient compliance and ensure product integrity are fuelling rapid expansion in this segment.

Usage Mode Insights

Why Did The Single Use Systems (SUS) Segment Dominated The Biopharma Plastic Market?

The single use systems (SUS) segment held the largest share in the biopharma plastic market in 2024. Single use systems are preferred for their ability to minimize cross contamination, reduce cleaning requirements, and accelerate production cycles in bio manufacturing. SUS components such as bags, tubing and connectors made from high quality plastics allow flexible, scalable and cost effective operations while complying with stringent regulatory standards. Their growing adoption in biologics and vaccines manufacturing has solidified their dominance in the market.

The multi-use/reusable systems segment is anticipated to grow with the highest CAGR in the market during the studied years. Reusable systems are gaining popularity as companies aim to reduce waste, improve sustainability, and optimize operational costs, innovations in sterilisable plastics and modular design allow these systems to be cleaned, validated, and redeployed multiple times without compromising safety or quality. The increasing focus on environmentally friendly practices in the pharmaceutical industry is driving rapid adoption of multi-use solutions.

End User Insights

Why Did The Biopharmaceutical Manufacturers Segment Dominated The Biopharma Plastic Market?

The biopharmaceutical manufacturers segment captured largest share of the market in 2024. These manufacturers rely heavily on high purity plastics for bioprocessing, storage, and packaging of biologics and vaccines. The demand for innovative single use and reusable plastic solutions to ensure sterility, reduce contamination risk, and sterling production continues to drive market dominance. Strong manufacturing infrastructure, research and development capabilities, and regulatory compliance further support this segment’s sustained prominence.

The CMOs (contract Manufacturing Organizations) segment is expected to experience the highest growth rate in in the market between 2025 and 2034. CMOs are increasingly outsourcing production to leverage cost efficiencies, advanced technologies, and specialized plastic based bioprocessing solutions. The flexibility offered by single use and multi-use plastic based bioprocessing solutions. The flexibility offered by single use and multi-use plastic systems aligns with the CMOs need to handle multiple products efficiently while meeting strict quality and regulatory standards, driving rapid adoption in this segment.

Distribution Channel Insights

Why Did The Direct Sales Segment Dominated The Biopharma Plastic Market?

The direct sales segment held the largest share in the biopharma plastic market in 2024. Direct sales channels allow manufacturers to engage closely with end users, provide technical support, and ensure the delivery of specialized plastics that meet regulatory and quality standards. This model is especially important for high value, customized products such as single use systems, bioprocessing equipment, and specialty packaging solutions, reinforcing the dominance of direct sales in the market.

The online/e-commerce segment is projected to expand rapidly in the market in the coming years. Online platforms offer convenience, faster order processing, and access to wider range of products, making it easier for smaller biopharma firms and CMOs to procure specialized plastics and components. The digitalization of supply chains, coupled with growing adoption of e-commerce in the pharmaceutical industry, is accelerating the growth of this distribution.

Regional Insights

Why Is North America Dominating The Biopharma Plastic Market?

North America holds the largest share of the global biopharma plastic market, driven by its mature pharmaceutical and biotech industries, strong research and development infrastructure, and high healthcare, gene and cell therapies, all of which demand high purity plastics and advanced packaging solutions. Regulatory frameworks and technological readiness also favour faster adoption of innovation plastic materials and components, helping North America maintain its dominance.

In the United States, the biopharma plastic market is propelled by robust demand for specialized packaging, advanced biologics manufacturing, and strong focus on maintaining cold-chain logistics for temperature sensitive drugs. Government support, investment in localized pharmaceutical production capacity, and public policy encouraging innovation in packaging and materials add momentum. The U.S. also benefits from having many of the major players in biopharma plastics operating or headquartered there, which promotes supply chain strengthened innovation in materials suited for strict regulatory and purity standards.

Why Is Asia Pacific The Fastest Growing Region In The Biopharma Plastic Market?

Asia Pacific is experiencing the fastest growth in the biopharma plastic market during the forecast period. The expansion of the pharmaceutical industry, particularly in biologics and generic drugs, is increasing demand for biopharma plastics. The rising prevalence of chronic diseases and increasing healthcare spending contribute to market growth. Advancements in healthcare infrastructure further boost the adoption of biopharma plastics in the region.

China is a key contributor to the biopharma plastic market. The growing prevalence of chronic diseases and the expansion of the pharmaceutical industry are increasing demand for biopharma plastics. The robust manufacturing of polyethylene (PE), polyethylene terephthalate (PET), and polypropylene (PP) biopharma packaging supports market growth. Extensive government support for the pharmaceutical and healthcare industries further drives the adoption of biopharma plastics.

Biopharma Plastic Market Top Companies

- BASF SE- Supplies medical-grade polymers and custom solutions for pharmaceutical packaging and bioprocessing.

- SABIC- Offers high-purity resins (e.g., PP, PE, PC) for drug delivery, medical devices, and single-use systems.

- Dow Inc- Provides polyethylene and elastomers for pharmaceutical films, IV bags, and medical tubing.

- DuPont de Nemours, Inc.- Develops specialized polymers (e.g., Teflon™, Delrin®) used in drug manufacturing and containment.

- Celanese Corporation- Manufactures medical-grade thermoplastics like POM and UHMW-PE for fluid handling in biopharma.

- Solvay SA- Supplies high-performance polymers (e.g., PVDF, PPSU) for bioprocess systems and sterile applications.

- Evonik Industries AG- Produces bioresorbable polymers and specialty plastics for drug delivery and medical implants.

- Röchling Group- Provides machined components from engineering plastics for biotech and cleanroom applications.

- Ensinger GmbH- Offers high-purity semi-finished plastics and parts used in pharmaceutical processing equipment.

- Saint-Gobain Performance Plastics- Manufactures tubing, film, and components for fluid transfer, filtration, and containment systems.

More Insights in Towards Chemical and Materials:

- Recycled Plastic Pipes Market : The global recycled plastic pipes market size was approximately USD 7.85 billion in 2024 and is projected to reach around USD 20.08 billion by 2034, with an estimated compound annual growth rate (CAGR) of about 9.85% between 2025 and 2034.

- U.S. Biodegradable Plastics Market : The U.S. biodegradable plastics market size is calculated at USD 2.14 billion in 2024, grew to USD 2.34 billion in 2025, and is projected to reach around USD 5.27 billion by 2034. The market is expanding at a CAGR of 9.44% between 2025 and 2034.

- Commodity Plastics Market : The global commodity plastics-market size was valued at USD 498.55 billion in 2024, grew to USD 513.26 billion in 2025, and is expected to hit around USD 666.76 billion by 2034, growing at a compound annual growth rate (CAGR) of 2.95% over the forecast period from 2025 to 2034.

- Plastic Injection Molding Market : The global plastic injection molding market size accounted for USD 12.45 billion in 2024 and is predicted to increase from USD 12.89 billion in 2025 to approximately USD 17.65 billion by 2034, expanding at a CAGR of 3.55% from 2025 to 2034.

- Corrugated Plastic Sheets Market : The global corrugated plastic sheets market size was valued at USD 1.85 billion in 2024, grew to USD 1.95 billion in 2025, and is expected to hit around USD 3.05 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.14% over the forecast period from 2025 to 2034.

- Plastic Compounding Market : The global plastic compounding market size was reached at USD 72.55 billion in 2024 and is expected to be worth around USD 148.83 billion by 2034, growing at a compound annual growth rate (CAGR) of 7.45% over the forecast period 2025 to 2034.

- Biodegradable Plastics Market : The global biodegradable plastics market size was reached at USD 13.19 billion in 2024 and is expected to be worth around USD 91.26 billion by 2034, growing at a compound annual growth rate (CAGR) of 21.34% over the forecast period 2025 to 2034.

- Plastics Market : The global plastics market size was reached at USD 651.55 billion in 2024 and is expected to be worth around USD 984.11 billion by 2034, growing at a compound annual growth rate (CAGR) of 4.21% over the forecast period 2025 to 2034.

- Biopolymers Market : The global biopolymers market size was valued at USD 19.85 billion in 2024, grew to USD 21.93 billion in 2025, and is expected to hit around USD 53.68 billion by 2034, growing at a compound annual growth rate (CAGR) of 10.46% over the forecast period from 2025 to 2034.

- U.S. Biomaterials Market : The U.S. biomaterials market size was valued at USD 68.16 billion in 2024, grew to USD 78.29 billion in 2025, and is expected to hit around USD 272.18 billion by 2034, growing at a compound annual growth rate (CAGR) of 14.85% over the forecast period from 2025 to 2034.

- U.S. Biodiesel Market : The U.S. biodiesel market size accounted for USD 15.34 billion in 2024 and is predicted to increase from USD 16.08 billion in 2025 to approximately USD 24.63 billion by 2034, expanding at a CAGR of 4.85% from 2025 to 2034.

- Bio-Based Platform Chemicals Market : The global bio-based platform chemicals market size was reached at USD 29.33 billion in 2024 and is expected to be worth around USD 48.46 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.15% over the forecast period 2025 to 2034.

- Biodegradable Plastics Market : The global biodegradable plastics market size was reached at USD 13.19 billion in 2024 and is expected to be worth around USD 91.26 billion by 2034, growing at a compound annual growth rate (CAGR) of 21.34% over the forecast period 2025 to 2034.

- Bio-Based Polymers Market : The global bio-based polymers market size was reached at USD 12.08 billion in 2024 and is expected to be worth around USD 58.36 billion by 2034, growing at a compound annual growth rate (CAGR) of 17.06% over the forecast period 2025 to 2034.

- Europe Bioplastics Market ; The Europe bioplastics market volume was reached at 7.45 million tons in 2024 and is expected to be worth around 40.16 million tons by 2034, growing at a compound annual growth rate (CAGR) of 18.35% over the forecast period 2025 to 2034.

- Biobased Insulation Material Market : The global biobased insulation material market size was reached at USD 70.20 Billion in 2024 and is expected to be worth around USD 119.34 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.45% over the forecast period 2025 to 2034.

- Bio-Based Polyurethane Market : The global bio-based polyurethane market size was reached at 4.86 million tons in 2024 and is expected to be worth around 10.73 million tons by 2034, growing at a compound annual growth rate (CAGR) of 8.24% over the forecast period 2025 to 2034.

- Bio-based Solvents Market : The global bio-based solvents market volume was reached at 13,00,000.0 tons in 2024 and is expected to be worth around 25,81,297.5 tons by 2034, growing at a compound annual growth rate (CAGR) of 7.10% over the forecast period 2025 to 2034.

- Bio-based Surfactants Market : The bio-based surfactants market volume was 5,96,016.3 tons in 2024 and is forecasted to reach around 5,96,016.3 tons by 2034, accelerating at a CAGR of 3.80% from 2025 to 2034.

- Asia Pacific Bioplastics Market ; The Asia Pacific bioplastics market volume was reached at 2.51 million tons in 2024 and is expected to be worth around 11.13 million tons by 2034, growing at a compound annual growth rate (CAGR) of 16.07% over the forecast period 2025 to 2034.

Biopharma Plastic Market Top Key Companies:

- BASF SE

- SABIC

- Dow Inc.

- DuPont de Nemours, Inc.

- Celanese Corporation

- Solvay SA

- Evonik Industries AG

- Röchling Group

- Ensinger GmbH

- Saint-Gobain Performance Plastics

- 3M Company

- Covestro AG

- W. L. Gore & Associates, Inc.

- Daikyo Seiko Ltd.

- West Pharmaceutical Services, Inc.

- Thermo Fisher Scientific Inc.

- Freudenberg Group

- Entegris, Inc.

- Nordson Corporation

- Moldex3D (CoreTech System Co., Ltd.)

Recent Developments

- In September 2025, Green technology firm Xampla has secured $14 million from European and UK sustainability focused investors to advance its mission of replacing 10 billion single use plastic products over the next five years. The company develops biodegradable alternatives made from plant proteins, such as packaging linings, dissolvable files, and fragrance capsules. This investment aims to accelerate licensing efforts and expand operations through collaborations in Europe e and Asia.

Biopharma Plastic Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Biopharma Plastic Market

By Product Type

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- Polytetrafluoroethylene (PTFE)

- Polyethylene Terephthalate (PET/PETG)

- Polycarbonate (PC)

- Polysulfone (PSU)

- Cyclic Olefin Copolymer (COC) / Cyclic Olefin Polymer (COP)

- Fluoropolymers (FEP, PVDF)

- Others (PA, PEEK, PPSU, etc.)

By Application

- Bioprocessing Equipment

- Single-use bags & bioreactors

- Tubing and connectors

- Filters & membranes

- Packaging

- Bottles & containers

- Vials & ampoules

- Closures

- Drug Delivery

- Syringes

- IV Bags & Systems

- Inhalers & injectors

- Diagnostic Equipment & Consumables

- Cartridges & cassettes

- Microfluidic chips

- Medical Devices (Biopharma Use)

By Usage Mode

- Single-use Systems (SUS)

- Multi-use / Reusable Systems

By End User

- Biopharmaceutical Manufacturers

- CMOs (Contract Manufacturing Organizations)

- Research Laboratories

- Diagnostic Labs

- Hospitals & Clinics (for injectable biologics)

By Distribution Channel

- Direct Sales

- Distributors / Wholesalers

- Online / E-Commerce Platforms

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5674

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor |

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.